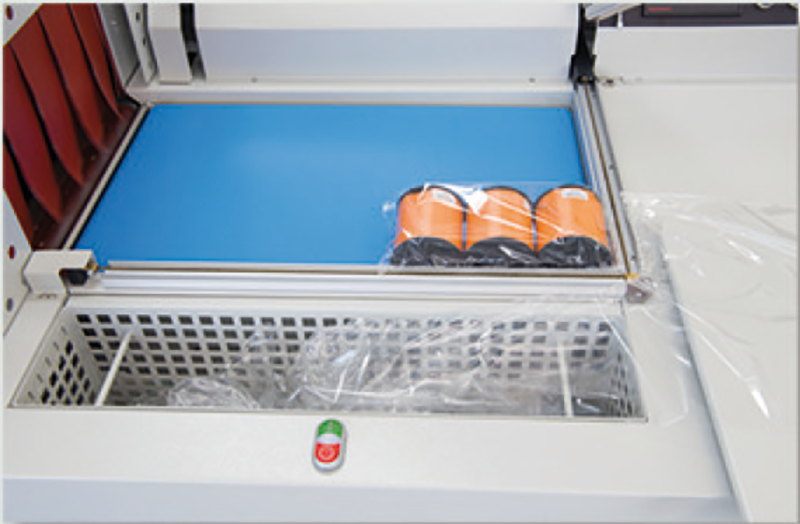

Compact shrink machine Profi Packer® SCK 8065 A Pro

These modern and technically mature compact shrink units are very powerful and very flexible in use. The compact design of the machines, consisting of an angle welding unit and shrink tunnel, is a space-saving and economically solution.

The units’ standard fittings include a continuously adjustable chain bar transport in the shrink tunnel, the height adjustment of the conveyor belt and a motorised closing of the welding frame by hand or foot switch.

The devices have a very modern and appealing design and work very reliably thanks to a robust and technically mature construction.

Compact shrink machine

Profi Packer® SCK 5844 A

Profi Packer® SCK 5844 A Pro

Profi Packer® SCK 8065 A Pro

Optionally with winding device for the film waste.

Compact shrink machine Profi Packer® SCK 8065 A Pro

Special properties of the machine:

- Air cooling of the welding system, for immediate cooling of the welding band after the welding process has been completed.

- Standard bar chain conveyor with 25 mm bar spacing.

- Fixed welding band, therefore very low wear with long service life.

- High quality, high performance shrink tunnel for perfect shrinking results.

- Under-air shrink tunnel (SCK 8065 A Pro) leads to an unprecedented shrink result in this machine class.

- Product table and film roll holder can be adjusted together.

- Modern, very simple LCD operating display.

- Adjustment options: Welding and heating temperature, cooling time, automatic cycle.

- Modern microprocessor control.

- Modular component design, hence especially easy to service repairs

- Robust steel frame design with the highest quality components.

- Energy saving, very low energy consumption.

- Easy height adjustment for a centred weld using a hand crank.

- Fan regulation via an inverter

- Tunnel speed via an inverter

- Standard wastebasket

- Triggering of the welding cycle via the hand or foot switch

- ISO 9001 manufacturing

- CE-compliant.

Profi-Packer® SCK 8065 A Pro, motorised closing of the welding frame, high-performance under-air shrink tunnel

Available options:

- Tunnel transport with plastic link chain

- Automatic waste winding

- Painting according to the colour of your choice.

| Profi Packer® SCK 8065 A Pro | |

|---|---|

| Welding frame dimension* | 800 x 650 mm (L X B) |

| Max. product height* | 200 mm |

| Power type | 400 V, 3 Ph., 50 Hz. |

| Average consumption approx. | 7,2 kW |

| Machine dimensions(L x B x H) | 3.250 x 1.255 x 1.600 mm (length with outfeed roller conveyor 3,550 mm) |

| Tunnel width | approx. 700 mm |

| Tunnel height | approx. 250 mm |

| Transport systems | Conveyor belt and bar chain conveyor |

| Cycle rate per minute** | up to approx. 15 packages |

| Max. film roll width | 700 mm |

| Max. film roll Ø | 280 mm |

| Film roll core Ø | 76 mm |

| Film thickness | from 7 to 60 mµ |

| Film material | Polyolefin fine shrink films, PVC; PLA and other organic films |

* It is not possible to combine all maximum dimensions!

** The performance specification is not binding (approx. value), as it depends on the product dimensions, the film type, the material thickness and the skill of the operating staff.

*Bilder und Videos können nicht enthaltene Sonderausstattungen zeigen.