Hood shrink machine Profi-Packer® SCH 4532, SCH 5844, manual for small batches

Hood shrink machines can be used to optimally package small batches of products of various types in shrink films.

First-class original and retail packaging is achieved. At the same time, this modern type of packaging protects the products from moisture, soiling and damage.

Hood shrink machines

Profi-Packer® SCH 4532

Profi-Packer® SCH 5844

Hood shrink machines Profi-Packer® SCH 5844

- Cooling of the welding system by air, for immediate cooling of the welding band after the welding process has been completed. This means no damage to the film material during manual advance feeding.

- Electric magnet for the hood.

- Fixed welding band, therefore very low wear with long service life.

- Easy height adjustment for the product grille.

- High-quality, quick-response finned heating units.

- High-performance fan, produces a shrinkage result that is unprecedented for this machine class.

- Product table and film roll holder can be adjusted together.

- Modern, very simple LCD operating display.

- Adjustment options: Welding and heating temperature, cooling time, shrinking time, automatic cycle.

- Modern microprocessor control.

- Modular component design for especially easy to service repairs.

- Robust and solid machine design with highest quality components.

- Energy saving, very low energy consumption.

- ISO 9001 manufacturing.

- CE-compliant

| Profi-Packer® SCH 5844 | |

|---|---|

| Welding frame dimension* | 580 x 440 mm (L X W) |

| Max. product height* | 250 mm |

| Power type | 240 V, 50 Hz, 1 Ph. |

| Connected load | 2.6 kW |

| Machine dimensions (L x W x H) |

1,227 x 745 x 1,135 mm |

| Height of the worktop | approx. 880 mm |

| Max. film roll width | 550 mm |

| Max. film roll Ø | 280 mm |

| Film roll core Ø | 76 mm |

| Cycle rate per minute** | approx. 5 to 8 pcs |

| Machine weight | 144 kg |

| Film thickness | from 7 to 60 mµ |

| Film material | Polyolefin fine shrink films, PVC; PLA and other organic films |

* It is not possible to combine all maximum dimensions!

** The performance specification is not binding (approx. value), as it depends on the product dimensions, the film type, the material thickness and the skill of the operating staff.

Semi-tubular films are used, which are inserted into the packaging machine with the opening facing forwards. The product is manually inserted into the welding and shrinking area together with the film.

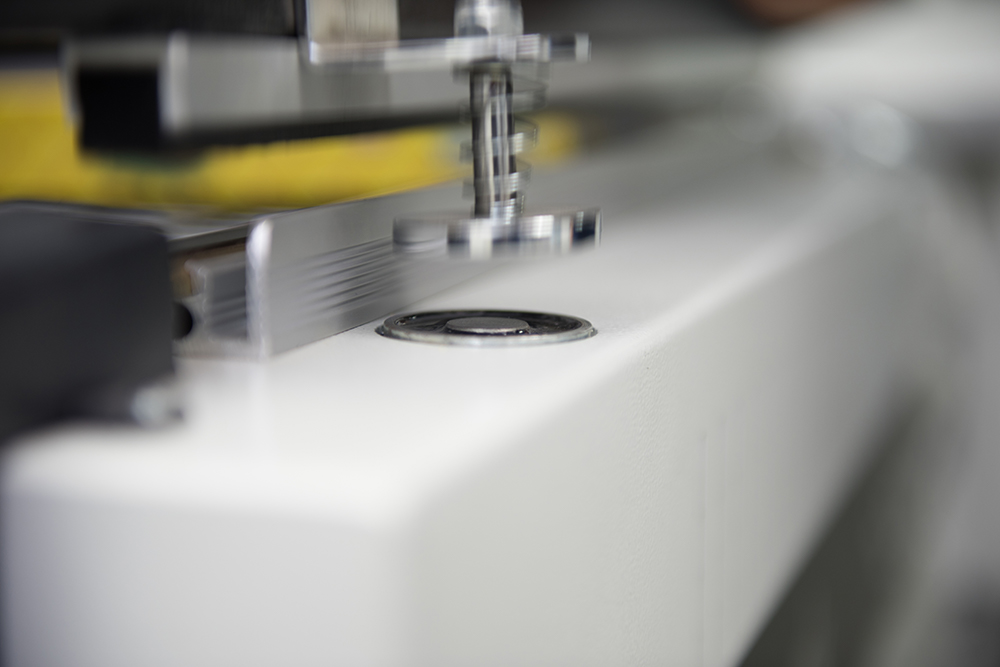

The machine’s transparent plexi-glass hood is manually closed, and at the same time a pulse-controlled cut-off welds in on all sides.

A precisely regulated hot-air fan shrinks the film material by means of the heating effect so that the film lies skintight against the item. The machine has an electromagnetic closing mechanism with precise control of the closing time.

During the welding and shrinking process, the operator can already insert the next product into the film.

Profi-Packer hood shrink machines are very flexible to use and easy to operate. They are especially suited for packaging single products and multi-packs in small batches. Our hood shrink machines have a modern design and feature a technically advanced construction.

*Pictures and videos may show optional equipment not included.